In part 1 of this series we explored the danger to people and equipment of falling fireproofing. In part 2 of this series we focused on different types of fireproofing. In part 3, we answered the popular question, when do we need to make replacement or repairs? Part 4 of the series looked at the risk of reduced fire resistance from deteriorated or damaged fireproofing in greater depth. Now, in the final part of this series, we will explain how to follow or establish guidelines for fireproofing.

Question 5: Where is fireproofing needed and why?

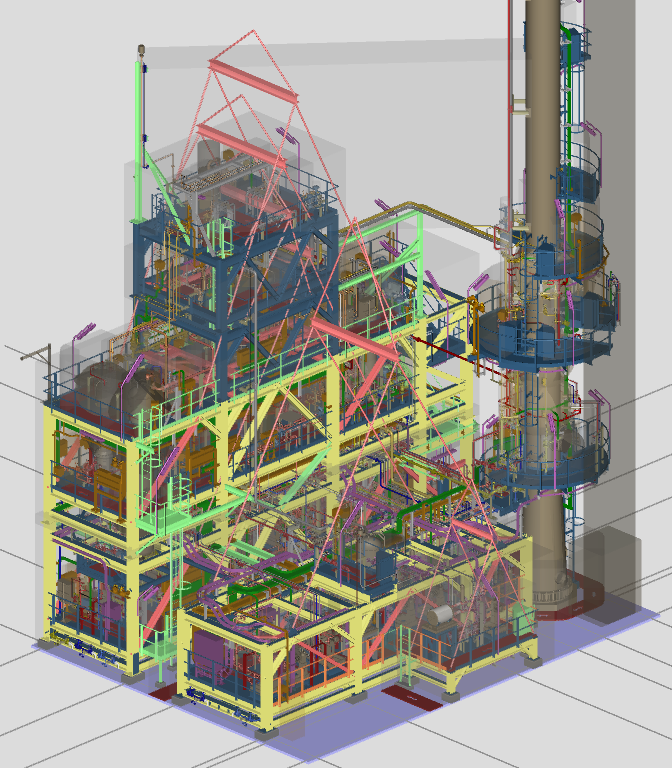

Fundamentally, for understanding where fireproofing is recommended, most industrial facilities have been following the guidance provided in API Recommended Practice 2218, Fireproofing Practices in Petroleum and Petrochemical Processing Plants, first published in 1988. Applying fireproofing to the correct locations of a structure is fundamental to the protection of the unit in a fire. However, very little is gained from over-application, yet much is lost such as excessive short- and long-term costs as well as long term safety concerns. Therefore, a thorough understanding of the structure, the equipment and process, fire protection principles, and industry guidelines are critical to providing the correct amount and type of fire protection only where needed. This is equally as important for new capital projects as it is for maintenance and reliability programs.

Capital Projects

For capital projects, establishing what does and does not require fireproofing is not only a critical cost consideration but can have a substantial effect on schedule as well. The more steel that must be fireproofed in the shop and the more scaffolding that must be erected in the field to fireproof the joints, the greater the impact on overall schedule and cost. Further, there are alternative strategies to simply putting in passive fireproofing or active fire suppression systems that are most effective if considered at the onset of the project when layout is being considered.

Fireproofing Assessment

Too much fireproofing has typically been for one of three reasons; the initial assessment pre-dates industry guidance, the unit in question has been modified in use, or the initial assessment was simply incorrect or over-conservative. You may ask, why should I care if an existing facility is over-fireproofed? The answer is, if it is in good condition, excessive fireproofing should be left alone. However, our experience is that many clients are spending a great deal of money fixing fireproofing that should simply be removed because it is of marginal value in a fire anyway.

Process and Equipment

Understanding the process and equipment involved, combined with a firm understanding of the structural frame and experience with fire protection principles and guidelines is the combination needed for an efficient and high value assessment.

With the experience of tens of thousands of structural and fireproofing evaluations behind us, Brindley Engineering has seen more structures over-fireproofed versus under-fireproofed. Brindley Engineering conducts assessments routinely as a core component of our Structural and Fireproofing Services and we have yet to conduct an assessment for a client that was not able to capture savings several times that which the assessment cost.

Talk to a Brindley Engineer Team member today ntriandafilou@brindleyengineering.com!

- Click here to read Part 1 of 5 Essential Fireproofing Questions

- Click here to read Part 2 of 5 Essential Fireproofing Questions

- Click here to read Part 3 of 5 Essential Fireproofing Questions

- Click here to read Part 4 of 5 Essential Fireproofing Questions

Read Part 1: What is the danger to people and equipment from falling fireproofing?

Read Part 2: What are the advantages and disadvantages of different types of fireproofing?

Read Part 3: What amount of fireproofing deterioration requires replacement?

Read Part 4: Our fireproofing appears to be in poor condition. Are our structures protected from a fire?

0 Comments