In part 1 of this series we explored the danger to people and equipment of falling fireproofing. In part 2 of this series we focused on different types of fireproofing. In part 3, we answered the popular question, when do we need to make replacement or repairs? Now in part 4 of the series we will look at the risk of reduced fire resistance from deteriorated or damaged fireproofing in greater depth and when we need to consider repairs.

Question 4: Our fireproofing appears to be in poor condition. Are our structures protected from a fire?

Removed, Split or Separated

One type of damage is when fireproofing is missing because it was removed, fell off, or split and separated. This creates gaps, holes, or large splits in the fireproofing, making it effectively absent in a specific area. Depending on where that occurs on the member and how that member is in service determines the level of risk associated with it. A common example of this is the installation of a pipe support in a structure already in service and fireproofed. What frequently happens is that craft labor will remove an approximately 1-foot wide strip of fireproofing from the bottom flange of a beam at mid-span and not replace the fireproofing at the end of the job. This gap in fireproofing would effectively render that beam un-fireproofed and largely ineffective in a fire.

Cracking

Another type of damage effecting fire resistance is from cracking. The impact from cracking changes substantially depending on the type, size, pattern, and location of the cracking. Of course, the greater the damage, the more severe the impact on fire-resistance by lowering the time required to reach a temperature where failure could occur. This damage and how it relates to the fire resistance ranges from the inconsequential to the ineffective. At what point it is highly problematic depends on location, quantity, member loading, and other variables.

General Deterioration

A third type of defect is due to general deterioration of the coating, typically associated with lightweight cementitious and intumescent fireproofing. These types of coatings nearly always require a topcoat of paint to protect them from UV deterioration and other types of chemical attack that don’t affect normal weight concrete nearly as much. Often these topcoats are forgotten or break down after a period of time and should be reapplied but seldom are. The coating will break down, become more porous, split, flake, dis-bond, and many other issues, all effecting the fire-resistance.

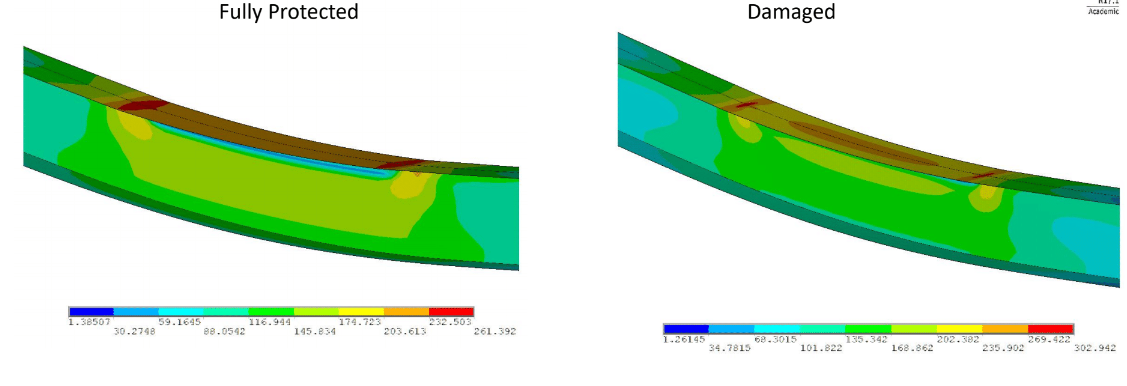

Brindley Engineering has done extensive research and analytical modelling on missing and damaged fireproofing. Combined with our high level of knowledge on structural systems in general, we are often asked to advise regarding what level of damage would require repair and the extensiveness of that repair depending on the service goals of that member and structure.

Talk to a Brindley Engineer Team member today ntriandafilou@brindleyengineering.com!

- Click here to read Part 1 of 5 Essential Fireproofing Questions

- Click here to read Part 2 of 5 Essential Fireproofing Questions

- Click here to read Part 3 of 5 Essential Fireproofing Questions

- Click here to read Part 5 of 5 Essential Fireproofing Questions

0 Comments