Brindley Engineering was requested to create a temporary piping solution near a complex series of pumps in order to keep a reactivated sludge (RAS) line in operation while piping for the line was replaced due to end of life conditions.

Temporary Piping Solution Near a Complex Series of Pumps

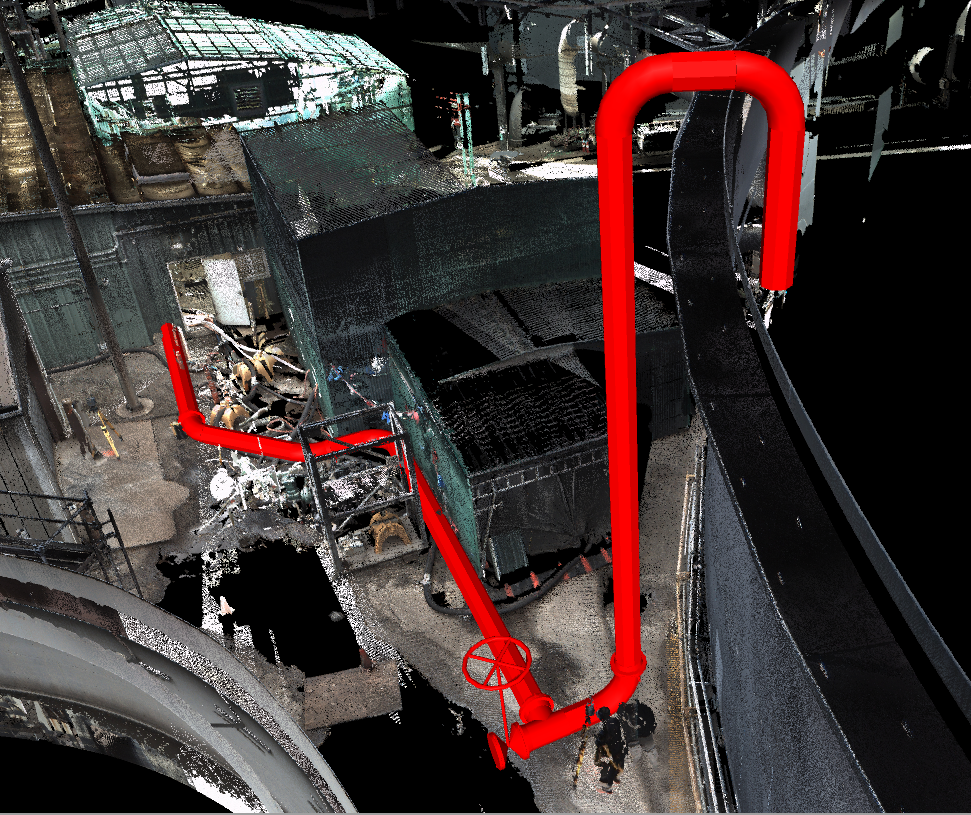

BE the Solution

We conducted an operability analysis to determine how best to tie-into the existing piping and the sequence of the tie-ins to minimize potential shut-down scenarios of this critical system. We then approached the same issues from a constructability and maintainability perspective to ensure the most efficient design while allowing on-going pump maintenance to continue. Next, we conducted a laser scan then created a 3D piping model and spool drawings to build the temporary line needed to reroute the RAS product. We imported the scaled model into a 3D point cloud to verify that there were no interferences in the routing and ensure that constructability and ergonomics were accomplished.

Our Challenges

The biggest challenge we faced was the complications of having to keep this system on-line while being replaced because shutting it down would have been highly costly. In addition, we had to overcome many other design challenges for items such as the pump nozzles not being level due to the floor being pitched and the pump bases were not truly level. In addition, the pumps were not perfectly in line with each other and design had to reflect the irregularities.

BE the Result

Keeping systems in operation whenever safely possible is a key to our Client’s success. The Brindley Team’s innovative approach to the work staging and the cost-effective layout of the temporary piping allowed this critical system to remain in operation throughout the replacement of key infrastructure.

0 Comments