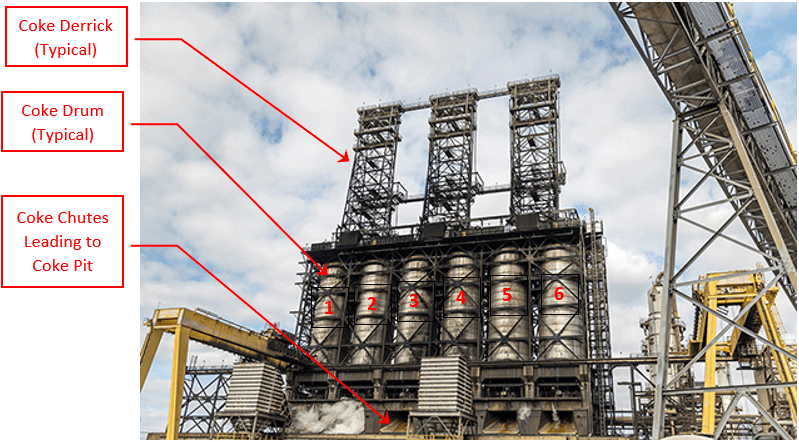

Industrial facilities are full of interesting structural engineering challenges. One of the most challenging structures are in refinery “Coker” units. A coker unit converts what would otherwise be a refining waste stream into valuable fuels, leaving behind industrial coke, which is similar in appearance and texture to charcoal. The coke is then commonly sent to steel mills as a fuel source in steel production. A typical coker has 4 or more coke drums, which are large vessels. The process results in the drums filling with a liquid product that is processed into the solid coke, then the coke is cut into small pieces within the drum, which is then dumped through a chute at the bottom of the drum into a pit for further handling.

One of the most challenging structures are in refinery “Coker” units

Using the photo above as an example, at any given time, drums 1 and 4 may be full, 2 and 5 half full, and 3 and 6 unloading. The drum loads when empty are 200,000 to 300,000 lbs., and can be 2 to 3 million lbs. when full. Structural engineers must account for the typical environmental loads on an open structure, but also must account for these extremely high dead and live loads and that the live loads are continually changing in location and magnitude.

Brindley Engineering works with coking units on a routine basis to conduct condition assessments in the field of these structures, develop engineering repairs for defective components, design new portions of these structures, provide construction engineering for the removal of the drums, and many other projects.

Some examples of what our structural engineers have done with cokers include:

- Built finite element analysis (FEA) models of the unit, applying the environmental loads including high wind and seismic loads, and analyzed the structural components in both a new and deteriorated state to determine risk of failure, both locally and due to systemic collapse.

- Assessed the condition of the in-situ concrete and designed post-tensioning systems to strengthen portions of these structures, such as reinforced concrete decks greater than 4 feet thick.

- Conducted complex analysis of the primary columns (often made of square, reinforced concrete, greater than 4 ft wide per side) to determine end of life and probability of failure, then used that data to construct construction repair sequencing plans and construction drawings

- Analyzed the Coker derricks to determine suitability for removal, then developed the engineered lifting and rigging plans to remove these structures, which are about the size of a 16-story building, made of steel trusses.

- Overseen field activities as the construction engineering team, representing the facility owner.

Brindley Engineering’s structural team has conducted these types of assessments, analysis, engineering, design, and construction oversights projects and many more. In part 3 of this series, we’ll focus on a fascinating sub-part of the coker unit called the coke chute, which is subjected to impact loads created from 3 million lbs. of coke being dropped onto the chute at temperatures greater than 500 deg F.

We are looking to expand our structural department. Start or continue your structural engineering career with Brindley today!

- Click here to read Part 1 of this series.

- Click here to read Part 3 of this series.

- Click here to read Part 4 of this series.

- Click here to read Part 5 of this series.

0 Comments