By Tom Brindley, CEO, Brindley Engineering

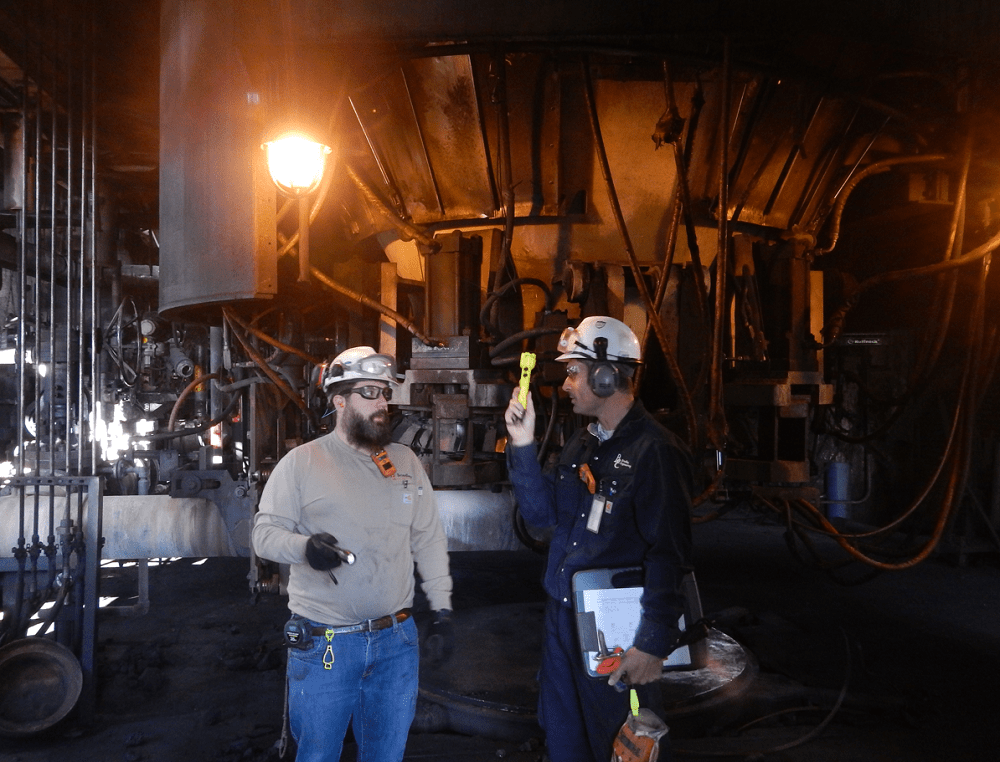

Reliability and maintenance of core infrastructure is a neglected area of focus for most facilities, leading to increased safety risk, maintenance cost, and decreased on-stream operations. Make sure you are protecting the backbone of your facility. Welcome to Brindley Engineering’s 10-part series on Infrastructure Reliability.

The Risk of Neglected Critical Infrastructure Can Add Up

Mechanical integrity programs have increased significantly over recent years in terms of the number of facilities with formalized programs and the sophistication of those programs. These mechanical integrity programs have largely focused on pressure vessels, process piping, and machinery but have neglected critical infrastructure such as the structures supporting this equipment and piping, the electrical and instrumentation systems keeping them running and controlled, the tanks the product flows to or from, and the utility systems needed to keep the plant in operation. As time goes by, lack of investment in the maintenance of critical infrastructure accumulates into ever increasing risk and cost of repair.

To Plan or Not to Plan?

Many facilities either lack infrastructure programs altogether or their existing programs are ineffective for reasons such as difficulty in establishing and organizing these systems, inconsistent funding, lack of internal expertise, inadequate feedback on risk v. progress, and other issues, mostly stemming from the facility’s primary focus on pressure boundary integrity.

Tackling the Challenge

To tackle these challenges, Brindley Engineering has conducted numerous infrastructure reliability and maintenance projects and programs. In this 10-part series we will give an overview of various programs and projects that Brindley Engineering has had successful client outcomes on.

More From This Series:

- Part 2: Utilities – Water quality and the effects of impurities on on-stream operability

- Part 3: Electrical – Condition evaluation of critical motors, transformers, and UPS systems

- Part 4: Instrumentation – Level instrumentation and its effects on reliable operation

- Part 5: Piping – Loss of primary containment caused by poor pipe routing

- Part 6: Tanks – Settling, buckling, and fitness for service assessments

- Part 7: Structures – Structural degradation and the risk of systemic collapse

- Part 8: Fireproofing – Fireproofing degradation, fire safety and corrosion of underlying steel

- Part 9: Cooling Towers – Collapsed cells and effects on cooling water availability

- Part 10: Project Controls – Understanding the big picture in real-time

The development and execution of maintenance and reliability programs is a core service of Brindley Engineering across all discipline areas and has led to significantly improved operational reliability, improved safety, and lower maintenance costs.

0 Comments