An inside look at how Brindley Engineering trains its engineers to identify and assess defects and provide the highest level of fireproofing services.

Welcome to Part 3 of our series on how Brindley Engineering focuses on engineering training to identify, assess, and provide the highest level of fireproofing services. In part 1 we talked about fireproofing condition assessment strategies. In part 2 we explored defect likelihood. Today in part 3, we continue to talk with BE’s Chris Sedlacko to learn more about the BE fireproofing training program for its employees. We will discuss root cause and defect severity.

Quiz Question: What is the most common root cause for fireproofing defects?

A. Improper surface preparation

B. Freeze / thaw

C. Fire damage

D. Underlying steel corrosion

Q: What are some root causes for concrete cracking?

A: Temperature & shrinkage, embedded steel corrosion, freeze/thaw, structural movement, and sealant failure.

Q: What are some root causes for spalling and delamination?

A: Cracking, insufficient concrete cover, anchorage failure, carbonation, chloride exposure, impact damage, poor consolidation, fire damage, improper substrate preparation, steel corrosion, freeze/thaw, and sealant failure.

Q: What are some root causes for mastic defects?

A: UV damage, improper material for environment (indoor material not rated for outside exposure), moisture absorption, impact damage, improper surface prep, fire damage, sealant failure, and poor detailing.

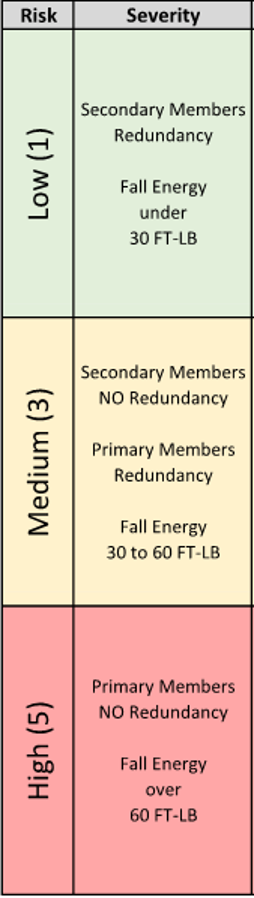

Q: How is defect severity categorized for concrete defects?

A: Concrete fireproofing defect severity is based solely on the expected result of the falling concrete. The determination of defect severity for mastic fireproofing is based on two failure modes:

- Expected result of the falling mastic

- Potential structural failure due to trapped moisture and underlying steel corrosion

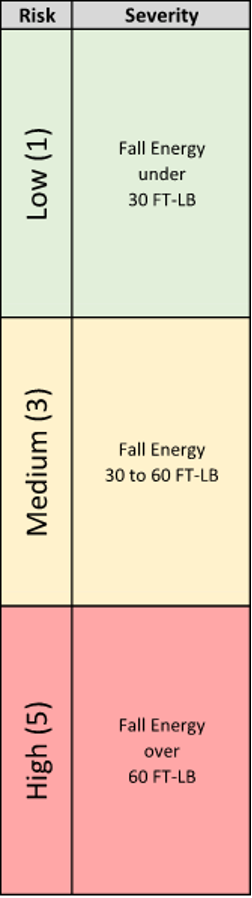

Q: How is defect severity measured?

A:

High Severity

-

- Fall Energy of 60 LB-FT or greater (3-LB at 20-FT).

- Drop that may result in fatality.

- Drop that may result in major injury.

- Drop with potential to destroy major pumps or equipment.

- Drop with potential to cause an explosion or fire.

- Drop with potential to cause spill.

Medium Severity

-

- Fall energy between 30 LB-FT and 60 LB-FT (3-LB from 10-FT to 20-FT).

- Drop that may result in minor injury (recordable).

- Drop with potential to destroy minor equipment.

- Drop with potential to cause minor damage to critical equipment.

- Drop with potential to cause spill.

Low Severity

-

- Fall energy 30 LB-FT or less (3-LB less than 10-FT).

- Drop that may result in first aid or no injury.

- Drop with potential to cause minor damage to minor equipment.

Q: What is API 2218? Why is it important?

A: API 2218 is a guideline that uses facility configuration and equipment knowledge as a means of identifying potential liquid hydrocarbon release locations and extent of resulting pool fires. Training our inspectors in the use of this guide assists in determining the defect severity, as they gain knowledge of where fireproofing is and is not needed throughout operating units.

API 2218 fireproofing need assessments are important to determine where fireproofing is recommended by industry standards. Brindley Engineering’s integrated engineering team of process, mechanical and structural engineers is ideally suited to assess units, determine hazard envelopes, and review active and passive systems. These evaluations typically identify areas of deteriorated fireproofing that can simply be removed (not replaced), resulting in cost savings and reduced maintenance needs.

Check out our recent case study: API 2218 – Fireproofing Recommended Practices in Petroleum and Petrochemical Processing Plants.

About Brindley Engineering Brindley Engineering was founded with a vision to provide the highest level of service to clients in capital & maintenance projects, reliability initiatives, and construction solutions. We’ve developed a world-class, multidisciplinary team of engineers, technicians, and designers that share that vision.

- Read Part 1 of this series.

- Read Part 2 of this series.

- Get in touch today!

0 Comments