In part 1 of this series we explored structural evaluations and risk assessment. Part 2 of this series, we focus on safety features and implications, the definition of ‘Safe’, and risk tolerance.

Theme 2: What is the minimum we must do to make our structures safe and keep them safe?

When it comes to industrial fireproofing, there are multiple safety concerns to think about.

A few are:

- collapse of a member or system

- failure of a walk-way system

- failure of a safety system such as handrails or ladders

- falling objects

Safety Features and Implications

These are structural failures that have direct safety implications. However, there are also a considerable number of safety considerations related to the degradation of structural systems to the point where they no longer perform the intended function. For example, steel supporting equipment or piping must maintain the level of stiffness intended in the pipe stress analysis or the equipment nozzles and piping could be overstressed, flange leaks could increase, rotating equipment could be misaligned, etc. Structural condition has direct safety implications to personnel in the unit as well as a direct operational reliability impact. Keeping structures performing as intended then has direct safety and business implications to a facility.

Defining ‘Safe’

When Brindley Engineering initiates a program with a new facility, one of the first things we do is align on what the definition of “safe” is. Obviously concrete ready to fall is an unsafe item but is the concrete 10 cubic inches and 5 feet off the ground or 10 cubic inches and 40 feet above a walkway? A steel beam may have 50% section loss from corrosion, but does it matter? A portion of an important structure may have wide-spread degradation but is intended to be replaced in a turnaround four years from now so will it last until then? These are the types of items Brindley Engineering works on determining with our Clients to align on what the facility’s needs are, which drives our recommendations.

Risk Tolerance

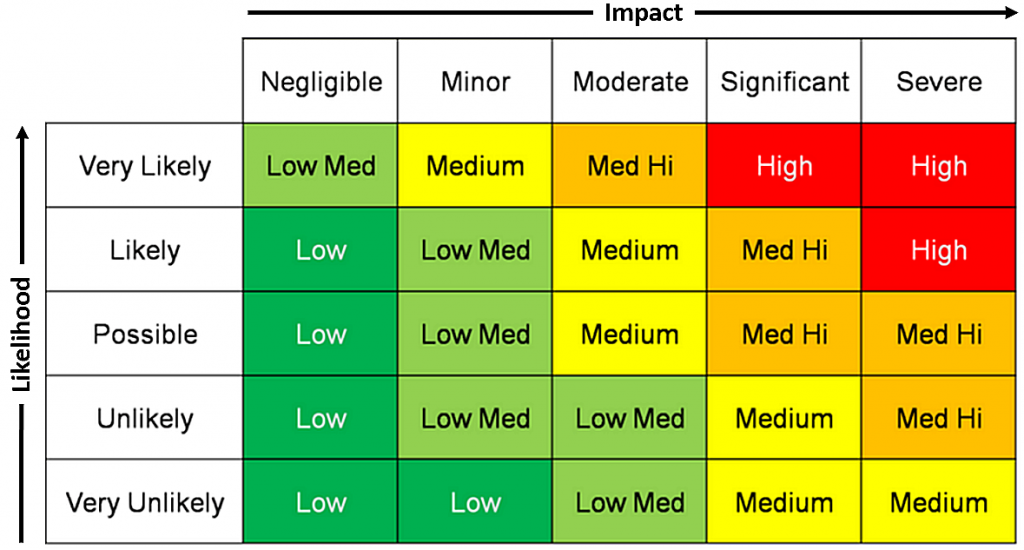

When we evaluate structures and consider the level of safety required and desired, many factors come into play such as type of unit, age of structure, location (arid / wetted), original construction quality, risk tolerance, and other factors. Brindley Engineering is experienced in evaluating these factors and helping our clients understand their current level of risk, how that compares with their peers, and what are common risk tolerance levels. We then identify the investment required to achieve and maintain an improved risk profile. When plant leadership determines their preferred approach, we then develop a plant-specific evaluation, repair and preventative maintenance plan that accounts for plant operating schedules to achieve these goals. We then implement the plan and provide regular reports that identify where the plant is in relation to its stated goals, how it changes over time, and future projections for planning purposes.

- Click here to read Part 1 of How to Cut Through the Smoke

- Click here to read Part 3 of How to Cut Through the Smoke

0 Comments