Brindley Engineering recently hired Khanh Phan, PE, PMP, a 30+ year industry veteran, as VP Project Services. This strategic move is part of Brindley Engineering’s expansion in Houston and beyond. We sat down to learn more about Khanh’s goals and ambitions for BE.

Q: Why Brindley Engineering?

A: Brindley Engineering is known for creative engineering solutions that simplify complex capital and maintenance projects, reliability initiatives, and construction solutions. At BE, we amplify our engineers’ creativity with proven project execution experience to deliver to our clients Best-in-Class Project execution. Many plants are finding it hard to keep up with the demand of new projects while addressing maintenance and reliability issues in their facilities. BE is well positioned for these types of work.

Q: What sets Brindley Engineering apart from the competition?

A: It’s very simple: our experience and our owner’s mindset. Anyone can claim to have experience and expertise in their respective fields, but Brindley has unprecedented SME experience that sets us apart – for real. For example, in addition to my new role our Houston office has added:

- A Process Engineering Manager with more than 40 years of experience in the design and operation of most refining processes and another Process Engineering Manager with over 40 years of experience in the chemicals and polymer industry – half of that experience is directly in production facilities, including plant management.

- A Project Director with over 34 years of experience – 25 in various roles at Marathon – working in all areas and aspects of a refinery. This Director has led Engineering and Maintenance departments at 5 different refineries and has directed the Mechanical Integrity and Process Safety Information and other elements of the Process Safety Management (PSM) program.

- A Senior Estimator with 40+ years of industry experience spanning a wide range of oil and gas business segments. Experience includes all phases of projects from concept into detailed design and projects ranging from $100k to $1B Total Installed Cost (TIC).

- A Mechanical Integrity / Fitness for Service SME with over 47 years of experience in the engineering, construction, operations, and maintenance associated with the Chemical Processing and Refining downstream industries. Certifications include API-510, 571 and 577.

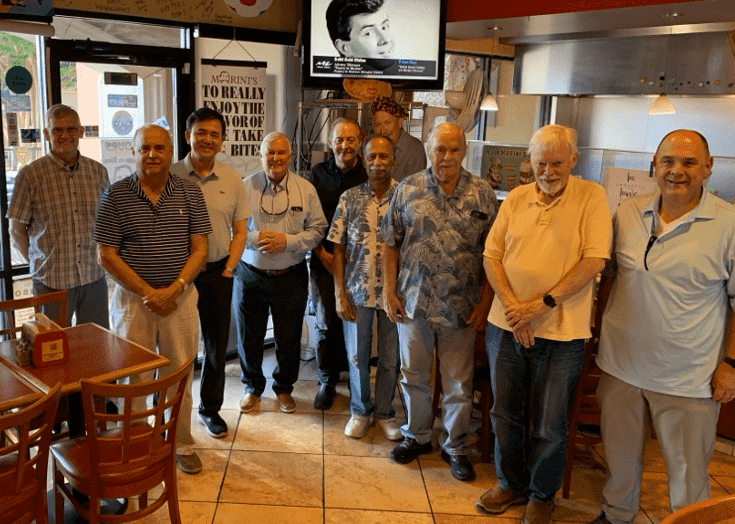

Most of these SME’s have known and worked with each other for decades. Simply put, Brindley Engineering not only brings experience and capabilities but our SME’s are known and respected in the industry.

Q: What questions should clients be asking when choosing a partner?

A: I’ll turn that around to say that Brindley Engineering will be sure to ask the tough questions to ensure that every project is well thought out prior to starting work. For example:

- Is the selected solution the most optimal overall?

- Is the early phase estimate a reliable indicator?

- Is the execution strategy consistent with current market conditions?

- How can Brindley Engineering help you to achieve your goals and commitments?

Q: What are BE’s core capabilities?

A: Brindley is a one-stop reliable source of quality work for capital and maintenance projects, reliability initiatives, and construction solutions. I will bucket our core capabilities as follows:

- BE is centered around a core PMC-based capability of consistently delivering superior results on capital investment programs across multiple markets.

- BE pairs experienced project professionals with execution infrastructure to enable a flexible model that is adapted to a variety of opportunities.

- Our approach maximizes return on invested capital to help our partners secure a competitive advantage.

0 Comments