Cooling Tower Reliability – Talk Data to Me: Interpreting Inspection Data

In Part 1 of this series we explored the importance of investing in cooling tower maintenance. Part 2 focused on what to expect while planning and executing a cooling tower inspection. In Part 3, we will explore how important the data is after a thorough cooling tower inspection and how the data should be analyzed.

Post Inspection Data: What Does it Mean?

After cooling tower inspections are completed, the most critical part of the structural analysis begins. The detailed cooling tower inspections provide data on the current condition of the cooling tower main structure and the amount of deterioration. However, this information does not indicate what needs to be done right away, what can wait until the next scheduled outage, or what can be disregarded altogether due to other components of the cooling tower itself.

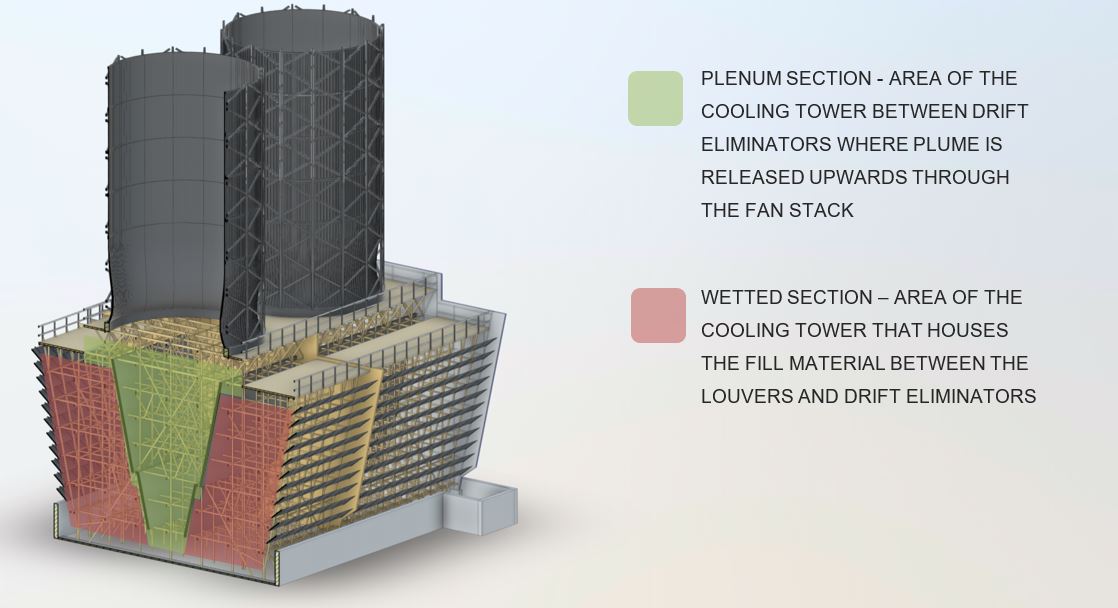

Analyzing the inspection’s 3D structural model (which has the visual representation and locations for all deficiencies, minor or major) is critical for the scope of work repair selection. Some areas can be repaired during a small outage, which will minimize operational impact and cost. Other, less accessible areas have the potential for scope growth from discovery once full access is attained and repairs begin. And most importantly, some repairs can only happen when major structural members are shored to allow for member replacement. The more significant the damage or the longer the expected run before the next scheduled outage, the greater the amount of analysis and planning required. See the diagram above clarifying the primary areas of the cooling tower.

Post Inspection Data: True Cost Analysis

Another essential part of the cooling tower analysis is the repair cost needed. Once the inspection is complete and the data analyzed, a repair estimate is completed. The estimate can be as detailed as +/-10% of Total Installed Cost (TIC), can be used as a metric to compare against bids, and are used to develop key performance indicators for maintenance contractors. Having this type of information prior to construction is essential for most of our customers since it helps them to plan the repair timeframe, and provides insight to the possible total execution cost.

Post Inspection Data: How to Plan Based on What We Know

As a facility Owner, knowing the level of repair effort that will be needed prior to construction is crucial since cooling towers are critical for plant operations. Having the ability to effectively plan repairs and allocate the necessary amount of funds, resources, and schedule to avoid surprises during execution is one of the most important outputs from our reliability program. Without an independent inspection and data analysis, repairs are based solely on historical information or findings by the maintenance contractors during execution, which often leads to project overruns.

– Ronald Accomando, Brindley Engineering Account Manager,

Read Part 1: Industrial Cooling Tower Maintenance

Read Part 2: Industrial Cooling Tower Inspections

Read Part 4: Cooling Tower Repair Plan

Read Part 5: Cooling Tower Preventative Maintenance

Truly good work! This enables your customer to be better prepared.